Insert Molding Best Practices for Critical Applications – Part 2

Comments Off on Insert Molding Best Practices for Critical Applications – Part 2This is the second installment of a 2-part blog on Insert Molding for Critical Applications. If you missed the first half, you can find it here. Previously, we discussed this importance of material selection, surface treatment, and chemical compatibility for demanding insert molding components. Today, we will cover the other critical factors including insert placement […]

Insert Molding Best Practices for Critical Applications – Part 1

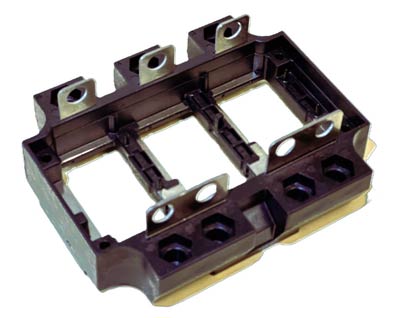

Comments Off on Insert Molding Best Practices for Critical Applications – Part 1Insert molding is a type of injection molding method that allows a pre-formed metal component to be placed within the molded part. A great example is a battery connector – where the metal is required for conductivity, while plastic offers design flexibility. Designing insert molded parts and processes for more demanding applications is not without […]

Scaling from Prototype to High-Volume Injection Molded Part Production

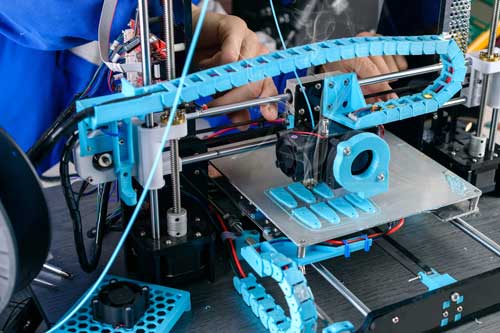

Comments Off on Scaling from Prototype to High-Volume Injection Molded Part ProductionYour prototype is a success. Excellent design, happy customers, and now it’s time to scale. The fun has just begun! The process of ramping up from a few hundred or thousand parts to hundreds of thousands or millions is where most product teams learn the hardest lessons. Manufacturing at scale takes more than just a […]

Injection Molding Best Practices

Comments Off on Injection Molding Best PracticesInjection molding is one of the most versatile and cost-effective manufacturing processes for producing high-quality plastic parts. But in order to get great results, you’ll need to follow injection molding best practices. This means paying close attention to every step throughout the process. Following these guidelines can help you maximize component quality and efficiency, while […]

Design for Injection Molding

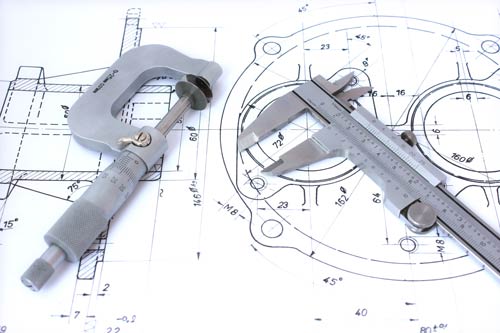

Comments Off on Design for Injection MoldingEssential Guidelines for Injection Molded Part Design & Manufacturing Design for injection molding is much more than just part design, it is a comprehensive process that must consider all aspects of the plastic component and the manufacturing process. These considerations primarily include part geometry, material selection, processing, tooling, quality and, of course, the financial aspects. […]

PDI Designated a 2025 Top Shop by Plastics Technology/Gardner Intelligence

Comments Off on PDI Designated a 2025 Top Shop by Plastics Technology/Gardner IntelligencePDI is very proud to be designated as one of the top plastics processors in North America by Plastics Technology, powered by Gardner Intelligence. We were recognized for exceptional performance metrics as follows: First-Pass Quality: We achieved 100% on products passing final inspection on the first attempt—testament to our passionate commitment to producing quality parts […]

Advanced Plastic Injection Molding Techniques

Comments Off on Advanced Plastic Injection Molding TechniquesBeginning with its inception 150 years ago, plastic injection molding has grown to become an indispensable method for producing countless components from raw plastic. Although the basics remain largely the same since that time, the industry has seen the technology evolve, particularly in recent decades. These days, parts can be made much quicker and more […]

PDI Achieves Parker Hannifin’s Coveted “Gold Level Supplier” Status

Comments Off on PDI Achieves Parker Hannifin’s Coveted “Gold Level Supplier” StatusPDI is proud to be recognized by Parker Hannifin Corporation’s EMOE Division as a Gold Level Supplier. For companies to achieve this status, they must meet stringent criteria that demonstrate excellence in quality, delivery, innovation, and partnership. The Supplier Assessment Scorecard specifically outlines 5 sections as follows: Cost – achieving target cost objectives Delivery – […]

Understanding Tolerances in Plastic Injection Molding

Comments Off on Understanding Tolerances in Plastic Injection MoldingOften, the difference between a properly functioning part and one that fails prematurely comes down to tiny fractions. With plastic injection molding this principle is illustrated by tolerances. Controlling tolerances in injection molding isn’t just about hitting the required spec. It’s much more than that. It’s about making sure the end part is reliable, compatible […]

Choosing the Right Resin for Your Injection Molded Part

Comments Off on Choosing the Right Resin for Your Injection Molded PartMaterial selection is a critical factor when injection molding. Selecting the right resign for your injection molded part will be the difference between a product that performs as designed versus one that won’t and could prematurely fail. There are many types of resins available today, each with it’s own set of features, benefits and properties. […]