The Challenges of Color Matching and Consistency in Engineering Resins

Comments Off on The Challenges of Color Matching and Consistency in Engineering Resins

Color matching in plastic injection molding is often a key requirement. Colors are used for branding, safety, functionality and even operational reliability. Matching a color consistently across a run, or from job to job should be a fairly straightforward process, right? In reality, when it comes to high performance resins, it’s much more complicated. Achieving consistency is challenging when compared to commodity plastics such for many reasons. Today, we’ll look at them, and how they can be navigated.

Why Is Color Consistency Important?

Before we jump into the challenges, let’s look at a few examples of where color consistency is important:

Branding – The first, if not most obvious reason, is when colors are used to brand products. Power tools, medical devices, and electronics often use company color palettes in their product designs. As any marketer would tell you, when it comes to representing a brand, colors must always match – no matter the medium.

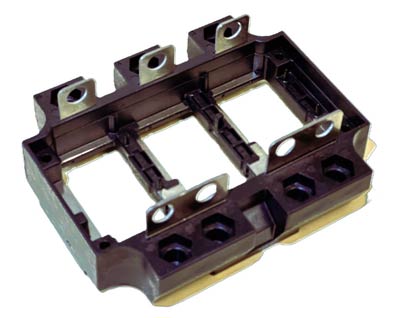

Identification – In addition to aesthetics, colors can also play functional roles. They are often used to help quickly identify things. A great example is a wire connector, which is color coded to help make sure that a technician selects the right one for the job. It’s a similar situation with medical triage, where surgical tools or drug delivery devices are color coded to indicate size, dosage, or specific uses. These are just a few of the many examples where colors are used for identification purposes.

Thermal Management/UV Resistance – here’s one you might not have thought of right away, but it’s important. Colors impact how the material behaves, particularly when subject to light and heat. Darker colors will absorb more radiation, while lighter ones will reflect it, staying cooler. This is critical for uses such as electronics enclosures. UV protection is also important for outdoor uses, as plastics can become brittle and crack.

The Challenges

Now let’s take at the main reasons why color consistency for engineering plastics remains a challenge:

Fillers – engineering resins are rarely used in their pure form, they are typically fortified with glass fibers, mineral fillers or flame retardants to meet functional requirements. The problem? Many of these have greyish or yellow tones to them. Fibers, on the other hand, will reflect light differently than the base, which could make the color look washed out.

High-Temperature Chemistry – certain applications call for extreme heat tolerance. This is where engineering resins like PEEK, PPS and Sulfones come in. However, the very heat that is used to process these resins often degrades the pigments that are used to color them. As a workaround, inorganic pigments or metal oxides may be used. While they are much more stable, they offer a limited color palette.

Based Resin Tint – many base resins, such as nylon and polyetherimide, have a strong natural color to them. However, their hues tend to shift from lot to lot. This is due to factors such as moisture content and age of the material.

Metamerism – now there’s a word you don’t hear every day! While you might not know it by name, you’re likely familiar with the concept. Metamerism occurs when two different parts can appear to match under certain lighting conditions, such as LED, then look completely different under natural or fluorescent light. This is particularly true when one part uses an engineering resin, and other parts may use commodity materials. Ensuring a match across these parts requires the use of spectrophotometer calibration, coupled with a deep understanding of light physics.

Conclusion

Color consistency in plastic injection molding isn’t always a requirement, but when the application calls for it, it can certainly be a challenge. Ultimately, it’s a balance act between chemistry, physics and also mechanical integrity. If you add too much pigment to force a color, this could degrade its physical properties. But when it’s non-negotiable, consistency can be achieved when working with an experienced team of designers, resin suppliers and injection molding companies.

Your prototype is a success. Excellent design, happy customers, and now it’s time to scale. The fun has just begun!

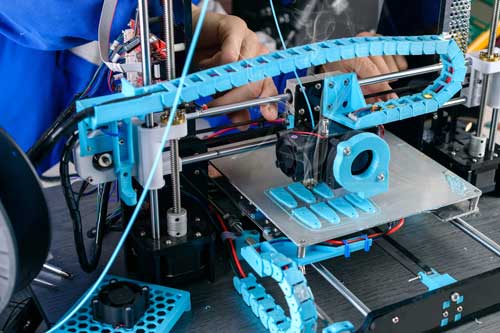

Your prototype is a success. Excellent design, happy customers, and now it’s time to scale. The fun has just begun! Prototype tooling is perfect for what it’s designed for: short runs and design flexibility. But things like aluminum molds, 3D fixtures, and soft tooling can’t handle the demands of production runs. Imagine if you are starting with 10,000 parts a year, and run 500 cycles per month. If you go to a million parts annually, you’re now at 5,000+ cycles per month. Your aluminum mold will be shot in three months, instead of three years.

Prototype tooling is perfect for what it’s designed for: short runs and design flexibility. But things like aluminum molds, 3D fixtures, and soft tooling can’t handle the demands of production runs. Imagine if you are starting with 10,000 parts a year, and run 500 cycles per month. If you go to a million parts annually, you’re now at 5,000+ cycles per month. Your aluminum mold will be shot in three months, instead of three years. One of the biggest sources of frustration when ramping up is the time it takes to successfully scale from prototype to production. While it can happen quicker, it’s not unusual for it to take up to 24 months to do. Steps such as tooling design, production and testing will likely take several months. Then you’ll need to budget time for tool sampling, iterations, and first article inspection. It takes time to design and produce the molds. Teams that attempt to shortcut this process often sacrifice proper process validation, deal with single-source vulnerabilities, and may end up with expensive design changes.

One of the biggest sources of frustration when ramping up is the time it takes to successfully scale from prototype to production. While it can happen quicker, it’s not unusual for it to take up to 24 months to do. Steps such as tooling design, production and testing will likely take several months. Then you’ll need to budget time for tool sampling, iterations, and first article inspection. It takes time to design and produce the molds. Teams that attempt to shortcut this process often sacrifice proper process validation, deal with single-source vulnerabilities, and may end up with expensive design changes.

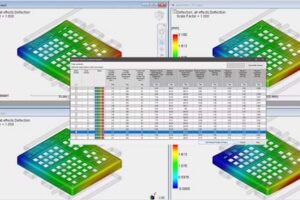

Process validation and documentation – establish processing windows through designed experiments rather than relying on trial-and-error approaches. Document validated parameters thoroughly and implement controls to maintain consistency across different operators and shifts.

Process validation and documentation – establish processing windows through designed experiments rather than relying on trial-and-error approaches. Document validated parameters thoroughly and implement controls to maintain consistency across different operators and shifts.

Application and environmental considerations go hand in hand. The components must be designed to withstand whatever threats they may be up against such as extreme temperatures, force, and chemical or UV exposure. Parts exposed to UV rays will definitely require specialty UV-stabilized materials, while having thicker sections will also help them maintain mechanical properties over time. For industrial applications, chemical resistance is often a critical factor. While food-grade components require specific material selections as well as surface finishes, with the goal of minimizing contamination.

Application and environmental considerations go hand in hand. The components must be designed to withstand whatever threats they may be up against such as extreme temperatures, force, and chemical or UV exposure. Parts exposed to UV rays will definitely require specialty UV-stabilized materials, while having thicker sections will also help them maintain mechanical properties over time. For industrial applications, chemical resistance is often a critical factor. While food-grade components require specific material selections as well as surface finishes, with the goal of minimizing contamination. Design for manufacturability, where parts are optimized against manufacturing complexity, cost and time, extends beyond basic moldability. Key considerations include:

Design for manufacturability, where parts are optimized against manufacturing complexity, cost and time, extends beyond basic moldability. Key considerations include: Today’s design for injection molding increasingly incorporates automation to help reduce labor costs and improve part consistency, quality and turn-time. Parts designed for robotic handling also benefit from specific grip features, balanced geometry for stable handling, and consistent orientation features.

Today’s design for injection molding increasingly incorporates automation to help reduce labor costs and improve part consistency, quality and turn-time. Parts designed for robotic handling also benefit from specific grip features, balanced geometry for stable handling, and consistent orientation features.

Beginning with its inception 150 years ago, plastic injection molding has grown to become an indispensable method for producing countless components from raw plastic. Although the basics remain largely the same since that time, the industry has seen the technology evolve, particularly in recent decades. These days, parts can be made much quicker and more precisely than ever before. In this blog, we’ll look at the advancements in plastic injection molding.

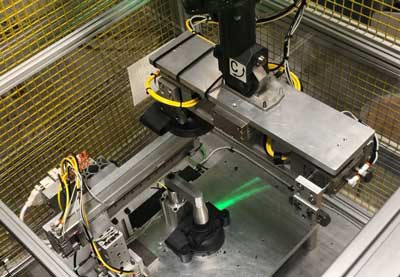

Beginning with its inception 150 years ago, plastic injection molding has grown to become an indispensable method for producing countless components from raw plastic. Although the basics remain largely the same since that time, the industry has seen the technology evolve, particularly in recent decades. These days, parts can be made much quicker and more precisely than ever before. In this blog, we’ll look at the advancements in plastic injection molding. Automation – is another key driver of molding which aids in managing complex assemblies and multi-step processes. For instance, robotic systems can now handle precise insert placement, part removal, and secondary operations with incredible accuracy.

Automation – is another key driver of molding which aids in managing complex assemblies and multi-step processes. For instance, robotic systems can now handle precise insert placement, part removal, and secondary operations with incredible accuracy.

Often, the difference between a properly functioning part and one that fails prematurely comes down to tiny fractions. With plastic injection molding this principle is illustrated by tolerances. Controlling tolerances in injection molding isn’t just about hitting the required spec. It’s much more than that. It’s about making sure the end part is reliable, compatible for assembly, and ultimately it will not cause the end product to prematurely fail. In this blog, we’ll explore the concept of tolerances in injection molding.

Often, the difference between a properly functioning part and one that fails prematurely comes down to tiny fractions. With plastic injection molding this principle is illustrated by tolerances. Controlling tolerances in injection molding isn’t just about hitting the required spec. It’s much more than that. It’s about making sure the end part is reliable, compatible for assembly, and ultimately it will not cause the end product to prematurely fail. In this blog, we’ll explore the concept of tolerances in injection molding.