PDI Designated a 2025 Top Shop by Plastics Technology/Gardner Intelligence

Comments Off on PDI Designated a 2025 Top Shop by Plastics Technology/Gardner Intelligence

PDI is very proud to be designated as one of the top plastics processors in North America by Plastics Technology, powered by Gardner Intelligence. We were recognized for exceptional performance metrics as follows:

First-Pass Quality: We achieved 100% on products passing final inspection on the first attempt—testament to our passionate commitment to producing quality parts every time.

Customer Retention: We ranked very high on customer retention, demonstrating our dedication to customer satisfaction.

Scrap Rate: Our scrap rate—measuring scrapped or reworked parts as a percentage of total production—scored an impressive 0%. (In this case, zero is great!) This reflects our superior quality systems and processes, benefiting both our customers and the environment.

This recognition validates what we’ve always known—that our team’s dedication to excellence sets us apart in the industry. We’re proud of these achievements and remain committed to maintaining the highest standards of quality, service, and environmental responsibility for all our customers.

Advanced Plastic Injection Molding Techniques

Comments Off on Advanced Plastic Injection Molding Techniques Beginning with its inception 150 years ago, plastic injection molding has grown to become an indispensable method for producing countless components from raw plastic. Although the basics remain largely the same since that time, the industry has seen the technology evolve, particularly in recent decades. These days, parts can be made much quicker and more precisely than ever before. In this blog, we’ll look at the advancements in plastic injection molding.

Beginning with its inception 150 years ago, plastic injection molding has grown to become an indispensable method for producing countless components from raw plastic. Although the basics remain largely the same since that time, the industry has seen the technology evolve, particularly in recent decades. These days, parts can be made much quicker and more precisely than ever before. In this blog, we’ll look at the advancements in plastic injection molding.

Understanding Conventional Injection Molding

Let’s start by looking at the foundation – traditional injection molding. This is a fairly simple process, with just four main steps, as follows:

- Plastic pellets are fed into a barrel which is heated, allowing them to mix and melt

- This produces a molten material which is then injected under high pressure into a closed mold

- The plastic then cools down and solidifies, taking the shape of the mold

- The part is then ejected, and the process repeats

This method has served manufacturers very well. In the early years, it was used to produce consumer goods such as buttons, combs, collar stays, and other common items. Over the years, its adoption spread into practically every industry. It’s no wonder why. Injection molding offers repeatability, cost savings for high volume runs, and allows for complex geometries and tight tolerances. But as market demands grow and evolve, so must the injection molding processes. Today’s buyers are looking for components that are lighter, stronger, more sustainable, and often more complex.

Modern Technology is Revolutionizing Injection Molding

It’s no secret: technology is the driver of modern injection molding innovation. It’s making parts more precise, making them more efficiently, and allowing them to do more, since material capabilities are improving as well. Computers can now monitor and adjust process parameters as needed, in real time. These include temperature, pressure, and flow rates. Real time adjustment helps ensure consistent part quality, while also reducing material waste.

Another key innovation, which is a favorite of the team here at PDI, is multi-cavity tooling. This technology allows for faster output, facilitating high volume runs, without sacrificing quality. Multi-cavity molds can be equipped with hot runner systems, which helps eliminate the waste of traditional cold runners, while making sure the mold uniformly delivers molten plastic where it’s needed. This also provides significant material savings, which is a good thing, especially for high value engineering plastics.

Injection molding can also be ultra precise thanks to micro-molding capabilities, which allows for production of parts with features measured in microns. This has made the process suitable for very demanding applications such as medical device manufacturing, where components including insulin pen needles or microfluidic devices require exceptional accuracy.

Pushing The Boundaries Even Further

Variations on the traditional injection molding process have helped further expand capabilities. Such processes include:

Insert molding – where plastic can be molded around a non-plastic part such as metal components, electronics, and other materials. For example, the electronics industry uses this method to have circuit boards, connectors and metal reinforcements easily integrated into housings. This eliminates additional process steps while reducing labor costs and improving product quality and reliability.

Multi-material injection molding – methods such as overmolding and co-injection allow manufacturers to combine different materials in a single cycle. This means components or products can be produced that have different properties across different sections. For instance, let’s imagine a tool handle with a rigid core and a soft-grip exterior can now all be produced in one seamless operation.

Gas-assisted injection molding – where pressurized gas is inserted into the mold cavity, creating hollow sections within solid parts. This enables the production of even more complex geometries than previously possible, while eliminating sink marks and reducing material usage

Automation – is another key driver of molding which aids in managing complex assemblies and multi-step processes. For instance, robotic systems can now handle precise insert placement, part removal, and secondary operations with incredible accuracy.

Automation – is another key driver of molding which aids in managing complex assemblies and multi-step processes. For instance, robotic systems can now handle precise insert placement, part removal, and secondary operations with incredible accuracy.

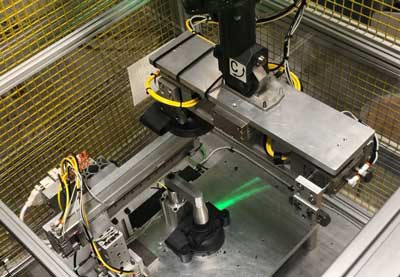

Multiple machines can be coordinated by advanced automation, which can also perform real time quality control with the help of vision systems. Automation can also handle things that could be challenging for people, particularly complex assembly sequences. This is very valuable for components such as automotive sensors or medical devices.

Advanced automation can coordinate multiple injection molding machines, perform real-time quality inspections using vision systems, and even execute complex assembly sequences that would be challenging for human operators. This integration is particularly valuable for high-volume production of intricate components like automotive sensors or medical devices.

Looking Forward

The injection molding industry continues evolving with developments in sustainable materials, Industry 4.0/artificial intelligence integration, and additive manufacturing hybrid processes. While these techniques don’t necessarily replace conventional injection molding, they certainly expand its capabilities. This offers manufacturers in virtually every industry new solutions to meet increasingly demanding performance, quality, profitability, and sustainability requirements.