Understanding Tolerances in Plastic Injection Molding

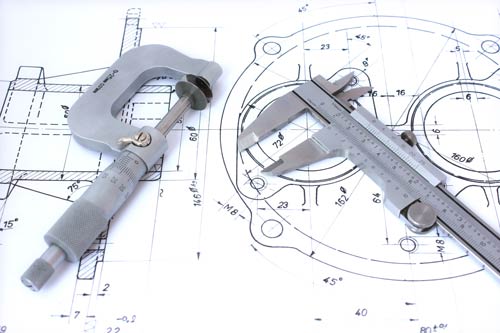

Comments Off on Understanding Tolerances in Plastic Injection Molding Often, the difference between a properly functioning part and one that fails prematurely comes down to tiny fractions. With plastic injection molding this principle is illustrated by tolerances. Controlling tolerances in injection molding isn’t just about hitting the required spec. It’s much more than that. It’s about making sure the end part is reliable, compatible for assembly, and ultimately it will not cause the end product to prematurely fail. In this blog, we’ll explore the concept of tolerances in injection molding.

Often, the difference between a properly functioning part and one that fails prematurely comes down to tiny fractions. With plastic injection molding this principle is illustrated by tolerances. Controlling tolerances in injection molding isn’t just about hitting the required spec. It’s much more than that. It’s about making sure the end part is reliable, compatible for assembly, and ultimately it will not cause the end product to prematurely fail. In this blog, we’ll explore the concept of tolerances in injection molding.

What Are Tolerances?

If you’ve been in manufacturing for any length of time, you probably have a good understanding of tolerances already. But let’s look at the general definition to make sure we’re all on the same page. Tolerances represent the acceptable range of variation in a part’s dimensions from its target, or nominal, value. In other words, by how much can we overshoot or undershoot the target? For instance, a part designed to be 50mm in length with a ±0.2mm tolerance could measure anywhere from 49.8mm to 50.2mm and still be acceptable. It’s a fairly straight-forward principle.

What Determines Tolerance Requirements for Injection Molded Parts?

There are several factors that influence tolerances. As mentioned earlier, these include considerations such as assembly compatibility. But above all, the end-use application determines the tolerance requirements. This is particularly true for mission and safety critical applications. For example, automotive components that interface with others will require tighter tolerances than trim pieces. Medical devices requiring precise dosing mechanisms could demand tolerances as tight as ±0.025mm. Household storage bins, on the other hand, could work just fine with tolerances exceeding ±0.5mm. Understanding the part’s role in the final assembly helps manufacturers to determine realistic and cost-effective tolerance specifications.

What Affects Tolerances in Injection Molding?

This is a great question, and we’re glad you asked! When it comes to injection molding, there are many factors that determine if a part is produced within tolerances. These primarily include mold quality, material impact, and process factors. Let’s look at each:

- Tool and Die Design Impact – the injection mold itself is perhaps the most critical factor in achieving tight tolerances, as mold construction quality determines the capability for achieving precision. Factors such as mold material hardness and machining accuracy of cavity surfaces establish the foundation for dimensional control. It’s also important that gates are designed and placed properly. Gates affect material flow patterns and help control shrinkage uniformity. Cooling channel design is also important, as it influences temperature distribution. If this isn’t right, the mold could have thermal gradients that will cause warpage. Other features, such as ejection systems, must be properly designed to ensure that parts are released without distortion.

- Material Impact – different plastic materials exhibit varying behaviors during the molding process which also directly affect tolerance capabilities. For instance, semi-crystalline materials such as nylon and polypropylene experience greater shrinkage during production. This makes it more challenging to hold tight tolerances compared to amorphous materials such as ABS or polycarbonate. Further, properties such as thermal expansion, moisture absorption, and flow characteristics all influence dimensional stability. Glass-filled materials offer improved dimensional stability but can introduce directional shrinkage variations that must be carefully managed.

- Process Factors – such as pressure, temperature and cycle time also contribute to dimensional variations during injection molding. Temperature fluctuations in the barrel, mold, or cooling system can cause inconsistent shrinkage rates. Injection pressure variations will affect how completely the mold cavity fills and how the material packs. Cycle time inconsistencies, particularly in cooling time, can lead to parts being ejected before fully stabilized. Additionally, contamination, wear, and damage to the mold can gradually shift part dimensions over longer production runs. Even environmental factors such as ambient temperature and humidity can influence finished part dimensions.

Preventing Dimensional Deviation

Maintaining tight tolerances requires systematic process control. It starts with a great mold and consistent material preparation to lay a foundation for repeatability. Process parameters must be carefully monitored and optimized such as injection speed, pressure, mold temperature, and cooling time. Regular mold maintenance is required to prevent wear-related drift, while implementing statistical process control helps identify trends before they result in out-of-specification parts. Technical molding principles, which emphasize understanding the relationship between process variables and part quality, help molders achieve consistent results.

Conclusion

While the concept of tolerances is relatively simple, achieving precise tolerances in injection molding requires understanding the complex relationship between design requirements, material properties, process parameters, and quality systems. Success comes from treating tolerance achievement as a systematic challenge that begins with realistic and achievable specifications and extends through every step of the manufacturing process. When properly managed, tight tolerance control transforms injection molding from a simple forming process into a precision manufacturing capability that supports today’s increasingly demanding applications.