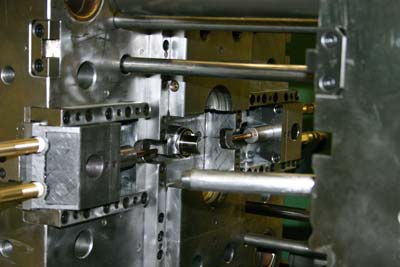

The Importance of Surface Finish, Texture, and Draft Angles in Injection Molded Part Design

Leave a Comment There are three aspects of plastic part design that are often overlooked, but crucial for manufacturing success: surface finish, texture, and draft angles. Understanding and optimizing each is critical for fabricating consistent, high quality plastic components efficiently.

There are three aspects of plastic part design that are often overlooked, but crucial for manufacturing success: surface finish, texture, and draft angles. Understanding and optimizing each is critical for fabricating consistent, high quality plastic components efficiently.

The first question that comes to mind: if these are so important, why are they often overlooked? We’re glad you asked! The reason is that these attributes are a function of the fabrication process, rather than the end product’s design and function. They fall under the umbrella of designing for manufacturability. So, it’s easy to see why these can be underappreciated by design engineers. But by doing so, they risk having issues and inefficiencies with part production. All of which leads to waste, extended turn-times, premature mold wear, and part quality issues.

Let’s take a look at surface finish, texture, and draft angles more closely, and how they relate to each other:

Surface Finish – refers to the finish of the part’s surface. Finishes fall into categories: smooth or textured. Smooth finishes may be either glossy or matte, and provide a clean elegant look. Textured finishes include grain finishes, stippled finishes, or others that provide grip, hide imperfections, or produce a certain aesthetic.

Surface finish is influenced by several factors including mold material, processing parameters, part material, and ejection mechanisms. Molds made from polished steel yield smoother finishes, while textured molds create specific surface patterns. Mold temperature, injection pressure, and cooling time can impact surface quality. As for the part material, different plastics have varying gloss levels, shrinkage rates, and flow properties, all of which affect the final finish. Finally, ejector pins and core pulls can leave marks if not designed optimally.

Texture – helps enhance the look, functionality, and performance of the finished component. Common options include leather-like, pebble/sandblasted, geometric patterns, and micro textures. Leather-like finishes enhance aesthetics, functionality, and performance. Pebble or sandblasted textures are durable and hide scratches. Geometric patterns provide functional grip, but may also be used for decorative purposes. Finally, micro-textures are ideal for parts where glare reduction or wear resistance is desired. Note that fine textures might require more intricate mold designs. One last thought on texture: textured molds can be more expensive to manufacture.

Texture – helps enhance the look, functionality, and performance of the finished component. Common options include leather-like, pebble/sandblasted, geometric patterns, and micro textures. Leather-like finishes enhance aesthetics, functionality, and performance. Pebble or sandblasted textures are durable and hide scratches. Geometric patterns provide functional grip, but may also be used for decorative purposes. Finally, micro-textures are ideal for parts where glare reduction or wear resistance is desired. Note that fine textures might require more intricate mold designs. One last thought on texture: textured molds can be more expensive to manufacture.

Draft Angles – often referred to as just “draft”, these are tapers in the mold that help release the part without damaging it. Optimizing draft is important for many reasons. Failure to do so could lead to visible scratches or steps on the finished component, which ruins the desired finish. It’s important to understand that surface finish and texture directly affect the required draft angles. Deeper textures require larger draft angles to avoid surface tearing during part removal.

Designing for Success

Remember, just because your plastic part looks perfect on screen, doesn’t mean it’s ready for optimal production. The key is to balance functionality and aesthetics by selecting surface finishes and textures that complement the product’s function and desired look while considering their impact on draft angles. Collaborate closely with mold designers and part fabricators to ensure optimal draft angles for achieving the desired surface finish within budget and feasibility constraints. Don’t hesitate to prototype and test parts to verify draft angles and surface finish quality before committing to full-scale production. The added cost will be worth it in the long run.

By understanding the intricate relationship between surface finish, texture, and draft angles, you can design and efficiently manufacture high-quality plastic parts that meet functional, aesthetic, and quality requirements.

Have questions about designing your parts for optimal manufacturability?

Contact us, we’re happy to help!